Reusing cartridges is both good for the environment and every reused cartridge, is one kept out of landfill. But what happens to the waste ink? Ninestar talks sewage as part of its focus on World Environment Day.

Reusing cartridges is both good for the environment and every reused cartridge, is one kept out of landfill. But what happens to the waste ink? Ninestar talks sewage as part of its focus on World Environment Day.

World Environment Day is on the 5th June this year and as part of their sustainability focus talks about inkjet and sewage.

Using remanufactured ink cartridges is better for the environment than a single use throw away cartridge ending up in a landfill.

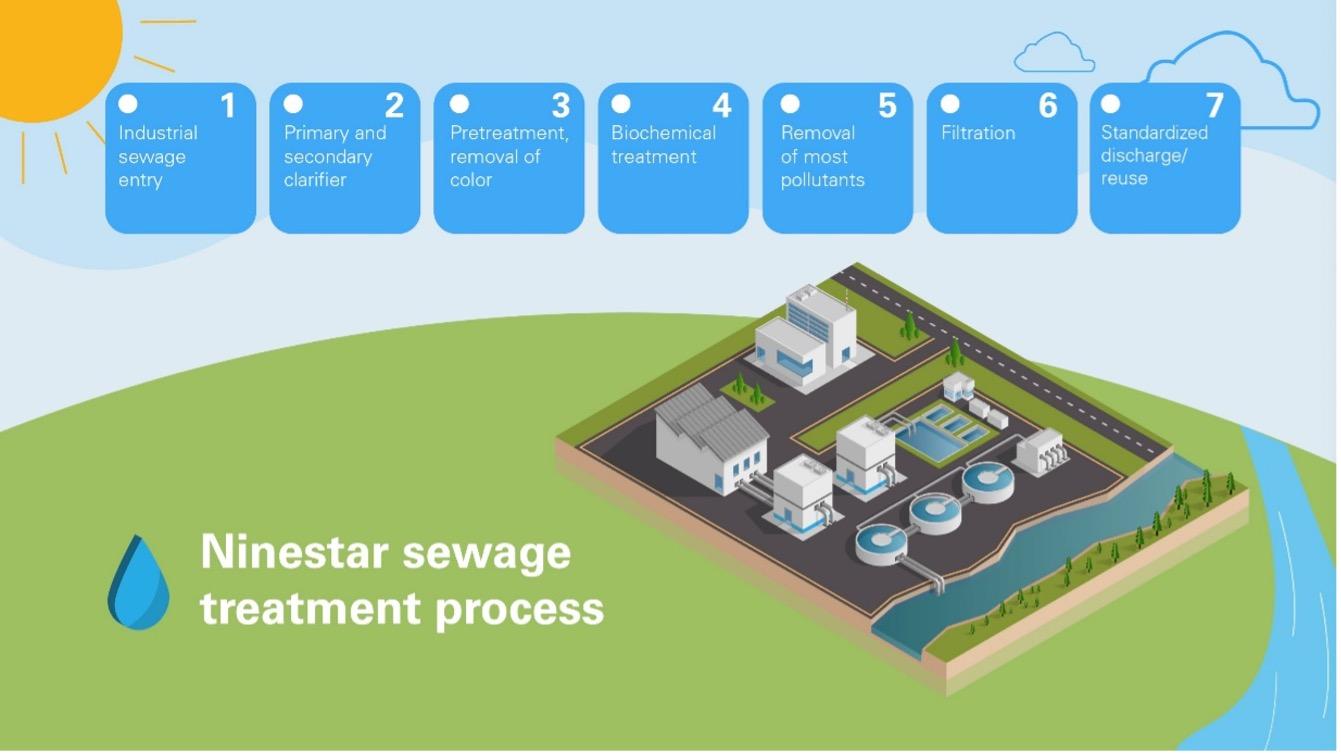

At the heart of producing a high quality remanufactured cartridge is the requirement to clean the residual ink out of the used original cartridge. This takes a lot of water which needs treating, otherwise the benefits of reuse are lost down the sewage drains, and the environmental choice credentials are lost.

Ninestar has invested 8 million RMB (€1.03 million / $1.25million), in a sewage treatment station that covers an area of 1500 m2 and able to process 800 m3 of sewage per day. As the World Environment Day focus, Ninestar invites you to take a look at it’s advanced sewage treatment station and see how they turn dirty water into clean water.

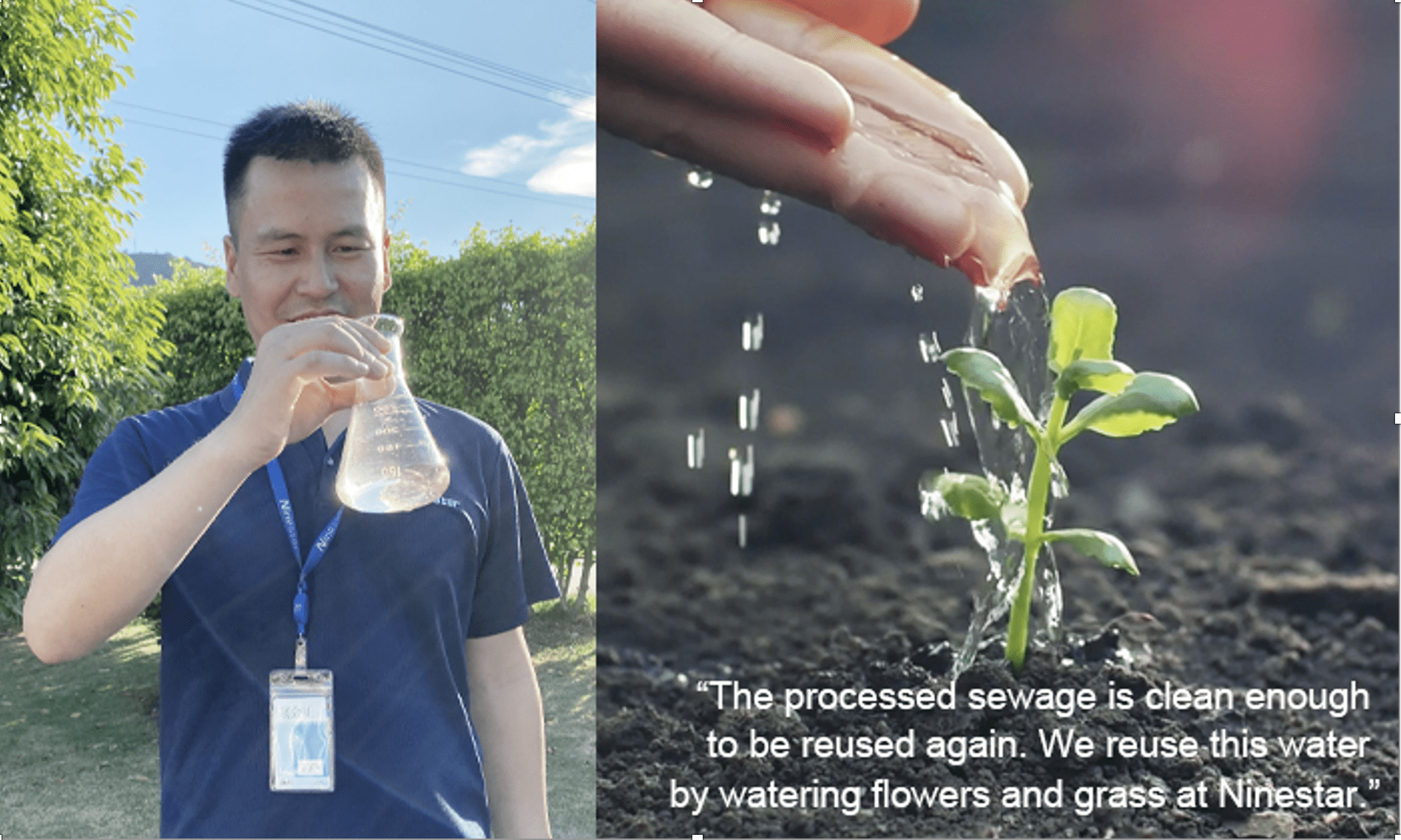

“In 2020, the annual treatment of inky wastes is 27375 m3 at our plant. Except for the strict pre-treatment, our engineers run regular after-treatment tests every 4 hours to guarantee the sewage will not be discharged until it is clarified completely. In fact, the processed black water is clean enough to be reused again. At Ninestar, we reuse this water in our daily life, like watering flowers and grass.” said Jarek Yang, senior product manager of Ninestar.

Ninestar is committed to reducing its carbon footprint and continually offering remanufactured range alternatives to customers coupled with its closed-the-loop recycling program. As the sustainable manufacturing is an imperative part of Ninestar’s “going green” strategy, Ninestar ensures that the environmental policy is implemented during its production.