The company said that Inkjet printers continue to be more popular among many user groups. Being able to enjoy colourful prints, at lower printing costs while being eco-friendly are the reasons behind the trend.

However, despite the advantages of inkjet printers, having clogged printheads can destroy the user experience in a heartbeat. Having broken lines and missing colours, all caused by clogged ink, while printing important documents is enough to make the user experience a negative one.

Usually when clogging happens, most consumers use the printer’s own print head cleaning function, which uses ink to flush and clean the heads. Ninestaradvises that this is not only is this a waste of ink, but it also increases the cost of printing and reduces efficiency.

Usually when clogging happens, most consumers use the printer’s own print head cleaning function, which uses ink to flush and clean the heads. Ninestaradvises that this is not only is this a waste of ink, but it also increases the cost of printing and reduces efficiency.

So, why do print heads get easily clogged? A Ninestar veteran ink engineer tells us what’s behind this.

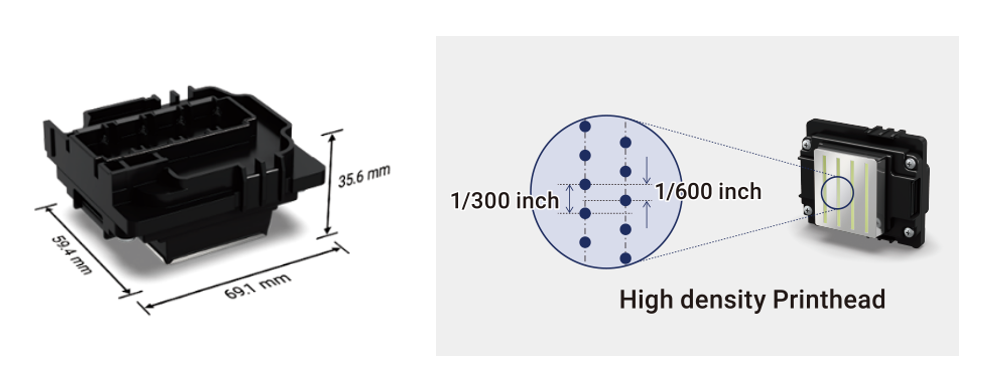

“The print head is extremely precise piece of technology,” said Kevin Cai, Senior Engineer of Ink R&D at Ninestar. “Let’s take the Epson I3200-A1 print head as an example: 3200 nozzles are distributed on the 0.004?print head, and the distance between the nozzles is only 1/300 inch.”

According to Cai, there are four main reasons for clogging:

- the printer is not used for a long time and the ink has dried and remains on the print head;

- the use of poor-quality ink (for example: poor compatibility, the impurities in the ink is oversized, etc.);

- dust (such as paper particles) are attached to the print head; and

- the air has entered into the ink pipe of the printer.

“Ninestar has been dedicated to the design of anti-clogging ink in the production process, the ingredients, and the quality testing to improve the user experience,” Cai noted.

Ninestar explained that it uses a nano-filtration process to remove impurities such as solid particles and colloids that cause printing clogging and adds “humectants” in a certain proportion to the ink to prevent the moisture in the residual ink on the surface of the print head from volatilising.

Ninestar explained that it uses a nano-filtration process to remove impurities such as solid particles and colloids that cause printing clogging and adds “humectants” in a certain proportion to the ink to prevent the moisture in the residual ink on the surface of the print head from volatilising.

“In addition to the anti-clogging designs during the R&D stage, we also carry out a series of rigorous quality tests to guarantee no clogging,” Cai added.

Compatibility test: Mixing Ninestar ink with the original ink;

Standby performance test: Simulating the user not using the printer for up to 30 days, then opening the printer and reprinting;

Printing test: Each series ink of more than 1000ml is tested on devices;

Ageing & freezing test: storing the ink in high and low temperatures.