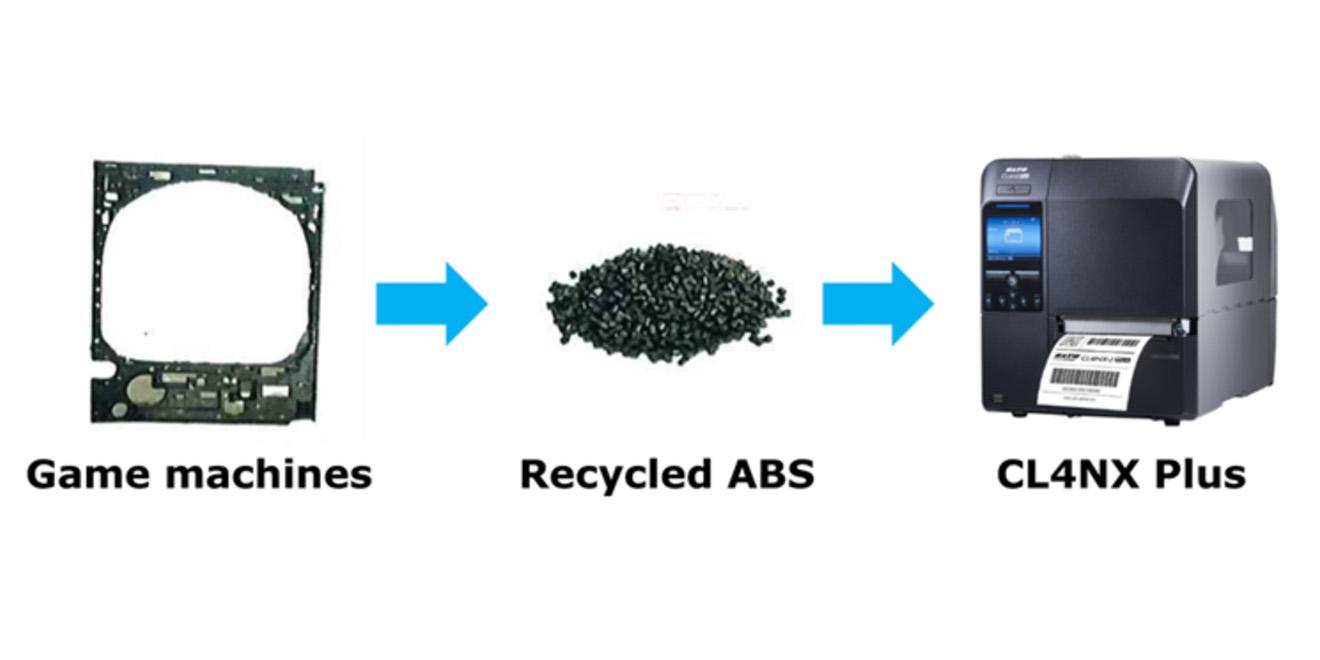

Recycled plastics for MFPs (multi-functional peripherals) developed by Konica Minolta have been used for SATO Holdings Corporation’s flagship industrial label printer line, the CL4/6NX Plus.

Konica Minolta has been working on five material issues, including using limited resources effectively, through its business. The Company aims to reduce the amount of the earth’s natural resources used by 90% or more by 2050 from the 2019 level. This will be accomplished by not only reducing the amount of resources used in products, but also by proactively switching to recyclable resources, such as recycled materials.

Konica Minolta has been working on five material issues, including using limited resources effectively, through its business. The Company aims to reduce the amount of the earth’s natural resources used by 90% or more by 2050 from the 2019 level. This will be accomplished by not only reducing the amount of resources used in products, but also by proactively switching to recyclable resources, such as recycled materials.

The company has been working on initiatives to maximise its contribution to reducing the use of the earth’s natural resources by externally deploying its know-how and technologies and promoting the use of recyclable resources.

As one of its specific initiatives, Konica Minolta is actively developing high-functionality recycling technology to use post-consumer recycled plastics for MFP parts, which require a high degree of functionality, and is expanding the use of recycled plastics to many products. To further reduce environmental impact by collaborating with more partner companies, Konica Minolta has also been encouraging other companies to use the recycled plastics through its Environmental Digital Platform. SATO responded to the call and decided to apply Konica Minolta’s technology to its products.

Recycled ABS (acrylonitrile butadiene styrene) developed by Konica Minolta derived from used game machines is used for about 40% of the casing of SATO’s CL4NX Plus and CL6NX Plus label printers. Given that the parts of label printers require flame resistance and strength, it was decided to use recycled materials characterised by superb flame resistance and strength already used in Konica Minolta’s MFPs.