Armor Battery Films unveils a new industrial site at La Chevrolière, near Nantes (Pays de la Loire, France), dedicated to the production of coated current collectors.

Armor Battery Films unveils a new industrial site at La Chevrolière, near Nantes (Pays de la Loire, France), dedicated to the production of coated current collectors.

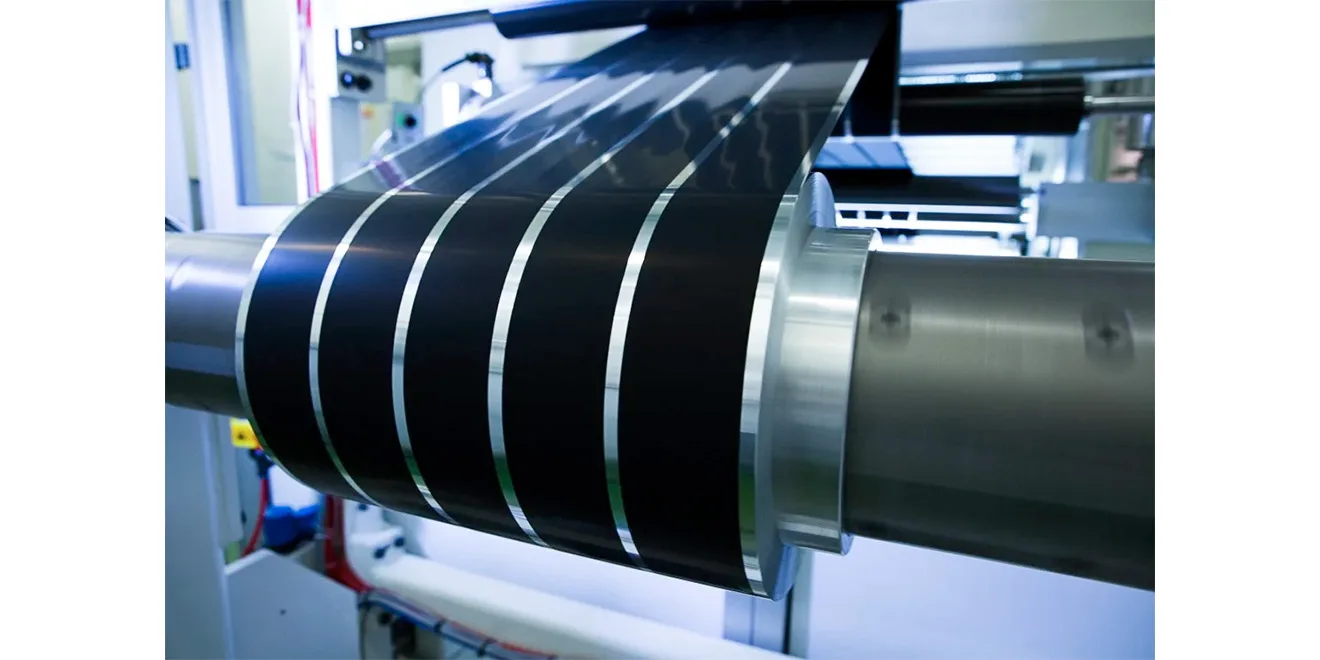

These are key components designed to enhance safety, performance and battery shelf life. This large-scale project has a dual objective: to acquire new R&D resources and to increase current production capacity fivefold.

“The industry has a role to play in structuring the economy and nationally (…) Now the battle will be to get back upstream to secure production elements, upstream of the battery.” Emmanuel Macron, 11 May 2023.

Committed to the development of energy storage systems, the En’ Safe current collectors developed by Armor Battery Films since 2015 have been designed to increase battery life by 20%, to charge them twice as fast, and to enhance their safety (corrosion, overheating, etc.). Thus, they contribute to the development of more efficient energy storage systems. Armor Battery Films’ customers are mainly European and North American, and these are battery manufacturers for eBuses, electric vehicles, data centres and networked energy storage.

This large-scale project has a dual objective: to acquire new R&D resources and to increase current production capacity fivefold, to 150 million m2 of coating per year, equivalent to 40 GWh. Such capacity would be sufficient to produce the equivalent energy from the 50 kWh batteries of 800,000 electric vehicles – i.e. the current EV fleet in France*.

This investment of €35 million ($37 million) in the new plant is divided into two main areas, one dedicated to the 8,000m2 building and the other to the equipment. The new facility, which is designed to operate 24/7d as an innovation centre, has a workshop for formulating inks, three coating and die-cutting workshops as well as a large storage warehouse.

More specifically, the entire 1st floor is dedicated to R&D activities, with three laboratories, including an anhydrous room. These areas are used to develop formulations, assembly and testing for batteries (buttons and pouches). Initially, the new site will house two production lines, but the building has been designed to accommodate a third, a project already planned for 2026/2028.

These new production lines can produce twice as quickly as the current line, and of handling widths up to 50% wider, with continuous and intermittent patterns. Around 10% of this investment was made possible by support from the French government via the “Première Usine or First Factory” initiative, part of France’s 2030 investment plan. Currently employing around 40 people, Armor Battery Films plans to employ a total of 180 people by 2030.

“This new site represents the largest single investment ever made by ARMOR GROUP since it was founded in 1922! The machines installed at the new site feature highly specialized technology, capable of coating both sides of the substrate at the same time and then drying it immediately. This will enable us to coat wider widths, intermittently if necessary, and to perform in-line cutting, which has not been the case until now. This is a major innovation.” explains Christophe Derennes, Operations Director for ARMOR GROUP.

“The battery industry is essential to Europe’s competitiveness and energy resilience. There are currently 20 mega-factories in operation. It is estimated that by 2025, battery production will cover at least 70% of European needs, and 90% by 2030. ARMOR GROUP is committed to this perspective of European industrial and energy sovereignty in an entrepreneurial spirit, both to capture market growth and to contribute to the re-industrialization of France. This new plant will supply strategic components for “Battery Europe”. Together with all our teams, we are happy and proud to be working for European energy sovereignty,” concluded Hubert de Boisredon.

*Source : Avere-France ; https://www.avere-france.org/publication/barometre-les-vehicules-electriques-et-hybrides-rechargeables-bouclent-un-tres-bon-premier-semestre-2023/