European remanufacturer adds new products to support office and large-format printing markets.

Altkin, a leading European supplier of alternative printing consumables, has announced a major expansion of its remanufactured cartridge catalogue, reinforcing its position in the circular economy and targeting broader adoption across office and professional printing sectors.

The move comes as global cartridge consumption remains high—more than 1.1 billion units produced annually, with an estimated 70% ending up in landfill. In response, Altkin has added dozens of new remanufactured models compatible with Kyocera and Epson A3 and A4 devices, as well as large-format printers and plotters used by architects and reprographic professionals.

The latest additions increase Altkin’s product catalogue to over 1,400 references, covering consumables compatible with 95% of printers installed across Europe. Products are offered under the OWA brand or as white-label alternatives, typically priced 30% below OEM equivalents.

“The printing sector opens up a field of easy and immediate actions that make it possible to reduce its environmental impact without requiring heavy investment. Whether private companies or public bodies, by opting for refurbished cartridges, these organisations are drastically reducing the amount of waste they generate and extending the lifespan of the products they use. It’s also, in very practical terms, a way of reconciling digital sobriety and economic performance,” said Gerwald van der Gijp, Altkin’s CEO.

Altkin’s expansion reflects growing pressure on both public and private sector buyers to meet sustainability targets. French procurement laws now require public entities to source at least 20% of their purchases from reused or recycled products.

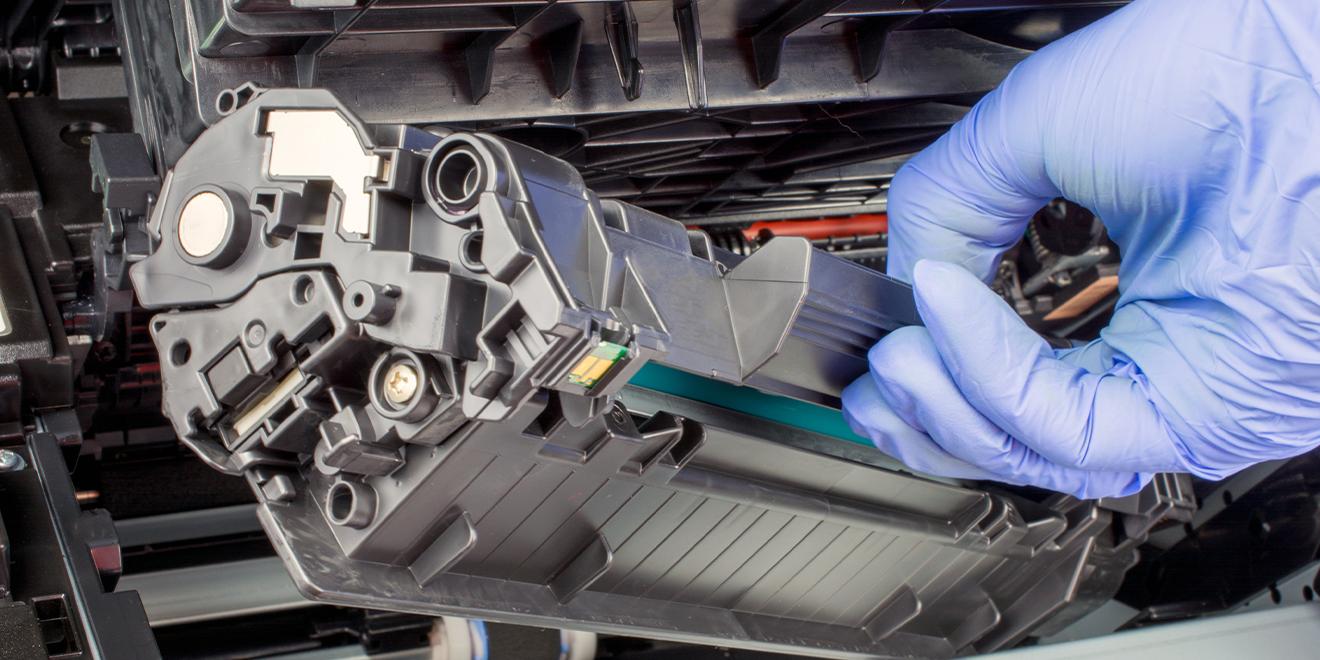

Remanufacturing remains less understood than recycling, but is considered by ADEME, the French environment agency, as the “most complete value retention process”. Unlike simple refilling, it involves a rigorous process that restores products to original or higher performance levels.

Altkin, with over three decades of industrial remanufacturing experience, processes more than two million cartridges annually. The work, mostly manual, is carried out in accordance with OEM patent compliance and depends on skilled labour.

As demand for cost-effective and sustainable printing solutions increases, Altkin’s strategy points to a maturing market for remanufactured consumables—one driven as much by regulation as by customer preference. “At Altkin, the remanufacturing process is carried out in compliance with manufacturers’ patents. Essentially manual, this activity is difficult to automate. It relies on skilled labour, which generates added value,” added Gerwald van der Gijp.