A new study reveals innovative multi-sensor technologies that could improve plastic identification and recycling.

A groundbreaking study published by a team of scientists led by Andréa de Lima Ribeiro at Helmholtz-Zentrum Dresden-Rossendorf (HZDR) and supported by researchers from Technische Universität Bergakademie Freiberg has unveiled innovative multi-sensor technologies that could transform plastic recycling.

A groundbreaking study published by a team of scientists led by Andréa de Lima Ribeiro at Helmholtz-Zentrum Dresden-Rossendorf (HZDR) and supported by researchers from Technische Universität Bergakademie Freiberg has unveiled innovative multi-sensor technologies that could transform plastic recycling.

Their findings hold significant potential for the cartridge remanufacturing and recycling industry, addressing long-standing challenges in identifying and recovering complex polymers.

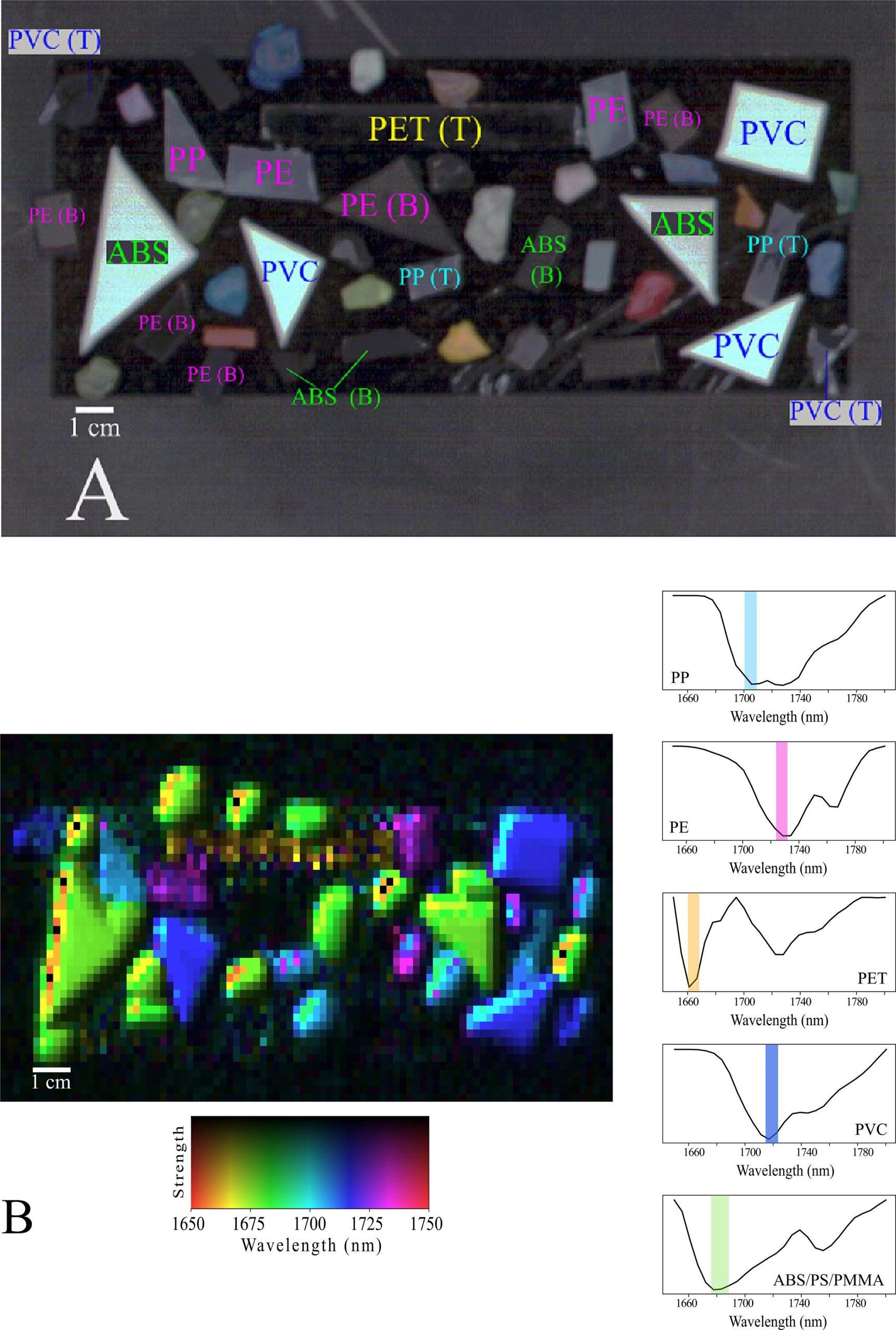

The research explores the use of hyperspectral imaging (HSI) and Raman spectroscopy, advanced techniques capable of identifying polymer types in diverse waste streams. These technologies are particularly adept at addressing the persistent problem of black plastics, a common material in printer cartridges, which traditional recycling methods struggle to process.

How it works

The researchers tested a dual approach: using HSI sensors to analyze the visible to mid-wave infrared spectrum for spatial and spectral mapping and Raman spectroscopy for detailed molecular identification. Together, these methods overcome the limitations of single-sensor systems, enabling precise, real-time sorting of complex materials at industrial conveyor speeds.

HSI demonstrated high effectiveness in identifying light-colored and transparent plastics, while Raman spectroscopy provided the critical capability of analyzing black plastics, even in the presence of challenging pigments. The combination ensures more accurate material recovery, preventing downcycling and preserving polymer-specific functionalities.

Implications for the cartridge recycling industry

The implications for the cartridge remanufacturing and recycling sector are potentially profound:

- Enhanced recovery rates: These technologies enable the precise separation of high-quality materials for reuse in remanufactured cartridges.

- Recycling black plastics: Many OEM cartridges are made with black polymers that current recycling systems cannot process effectively. The adoption of MWIR sensors and Raman spectroscopy could make these materials recoverable, reducing waste.

- Boosting compliance and sustainability: By ensuring recovered materials meet stringent EU regulations such as REACH and WEEE, the approach could help combat counterfeit and non-compliant cartridges, which often undermine sustainability efforts.

- Cost efficiency: Improved sorting efficiency could lower costs for remanufacturers, making them more competitive against OEMs and low-quality imports.

- Alignment with EU goals: This innovation supports EU sustainability initiatives, such as the Digital Product Passport (DPP), which could be implemented voluntarily by industry leaders to track product life cycles and improve transparency.

A step towards the circular economy

The collaboration between Helmholtz-Zentrum Dresden-Rossendorf and Technische Universität Bergakademie Freiberg represents a significant step forward in tackling one of the imaging industry’s key recycling challenges. While the research showcases promising advances in the ability to recover valuable materials from printer cartridges, the technology remains in its developmental stage. With further refinement and support, these innovations could significantly reduce environmental impact and bolster sustainable practices in years to come.

Addressing potential barriers

The adoption of advanced identification technologies such as hyperspectral imaging (HSI) and Raman spectroscopy could revolutionise cartridge recycling, but cost and operational changes may pose challenges for smaller companies. For these techniques to reach commercial readiness, further industrial testing and scaling are essential. Industry groups like the European Toner and Inkjet Remanufacturers Association (ETIRA) are well-positioned to advocate for funding, pilot projects, and practical adoption strategies to bring this technology closer to the market.

Exploring future opportunities

As Europe tightens environmental regulations and accelerates its sustainability agenda, this research highlights a pathway for innovation within the imaging industry. While widespread adoption may still be some years away, these technologies present an opportunity for remanufacturers to lead on green initiatives. Advanced polymer identification could help reduce waste, tackle compliance issues, and support the industry’s shift towards a circular economy. Early engagement with these developments could give the cartridge remanufacturing sector a vital competitive edge.

The full research paper is available on the Elsevier website here.